This article has been adapted from: https://www.innovationintextiles.com/smart-textiles-nanotechnology/flat-knitting-embroidery-and-diy-the-smartx-tools-for-tomorrow/

SmartX has just made its final call for project applications, with companies having until February 15th to secure up to €60,000 in funding each.

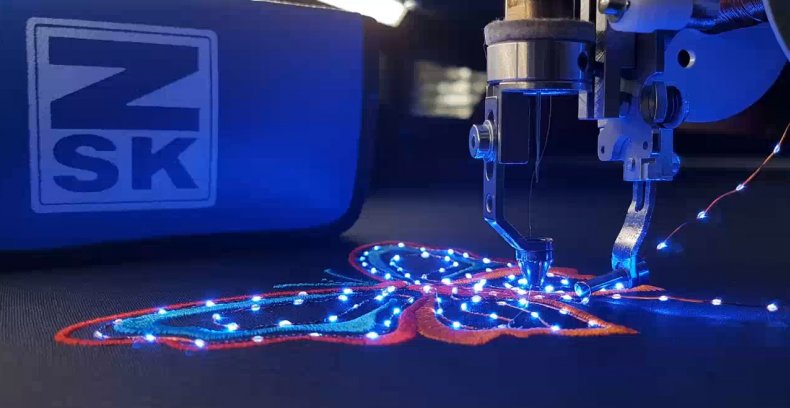

Melanie Hoerr, of ZSK, based in Krefeld, explained that for the creation of smart fabrics, three of the company’s separate embroidery heads can be combined in a single machine.

Brussels, Belgium

Backed by the European Union’s Horizon 2020 research and innovation scheme, the three-year SmartX Europe programme is supporting up to 40 smart textile projects with a total budget of €2.4 million and also providing a year of free coaching to help start-ups and small companies develop their technologies and establish the contacts they need.

“After selecting 20 projects worth over €1.5 million during our first two SmartX calls, we are now looking for our third and final cohort of trailblazer projects ready to conquer attractive market niches in the protection, sports, health and industrial end markets with disruptive smart textile solutions.” said Lutz Walter, secretary general of Textile ETP, a SmartX partner and the programme coordinator. The acceleration platform is driven by a consortium of 13 European partners from the textile and technology industries.

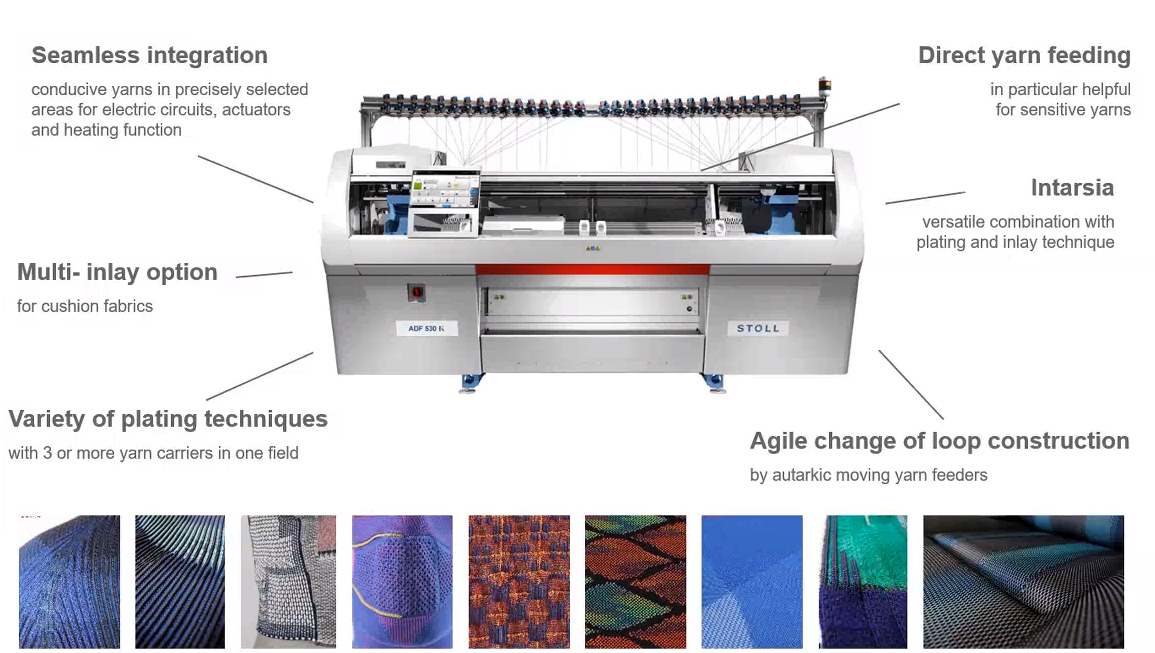

Stoll ADF

Alexander Behm, Stoll’s technical textiles product manager, explained how endless new smart fabric designs are possible on the company’s ADF flat knitting machine, via intarsia, plating and interlaying techniques for specifically integrating functional silver-coated polyamide or pure stainless steel or copper yarns to create flexible conductors for heating elements, sensors and actuators.

Many options have already been realised through Stoll’s partnership with Myant, and other commercial examples include the heated garments marketed by Germany’s WarmX.

A current medical application made with the Stoll system is a knitted gold mesh employed as an electrode within a device for the transfer of radio frequency (RF) energy in the treatment of menstrual pain.

Perhaps the most sophisticated product created to date on the Stoll system, however, is the glove created for Robert Bosch – Europe’s biggest supplier of automotive components, with 2019 sales of €77.7 billion.

Stoll’s seamlessly knitted glove created for Robert Bosch – Europe’s biggest supplier of automotive components.

© Stoll.

This seamless, 3D flat-knitted glove is made of yarn sensors which allow the wearer to sense and control applications in man-machine interactions.

An intarsia plating technique was employed to create the glove’s conductive and flexible sensors at the tip of each finger and a selective plating technique allowed the 12 electric paths, each based on single yarn feeders, to be precisely positioned.

“Sensors were integrated in a tubular structure and we employed elastic yarns to provide comfort to the glove’s customised shape,” Behm said. “The glove retains full breathability, despite its complex design.”